Damaged wood can become raw material for clothing

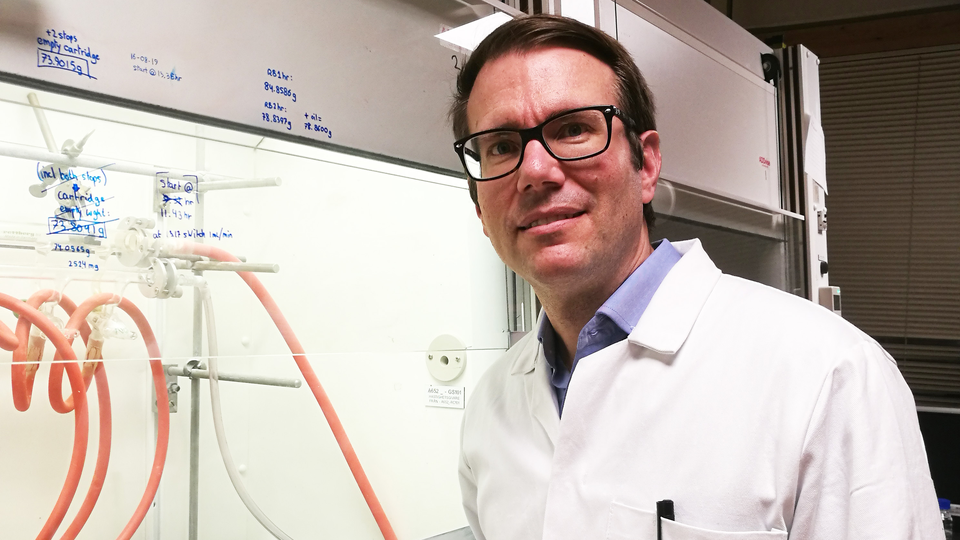

Wood damaged by the spruce bark beetle could be new raw material for clothes. This is the aim for a project within Mistra SafeChem, which is led by Joseph Samec, professor in organic chemistry at Stockholm University.

What is your function in Mistra SafeChem?

I am leading a project where we examine side streams from the forest industry, which is my field. In collaboration with professor Aji Mathew, we are focusing on generating a textile fibre from forestry residues. We are also investigating how to recycle plastics into textiles, a work Aji Mathew is leading.

Can you briefly describe your work?

We are looking into how to use bio-based residual streams, such as tops and branches from forestry, and wood damaged by the spruce bark beetle. Later we will also study bark. In collaboration with Skogforsk and Mellanskog, we seek how to get representative residual streams. We develop methods to fractionate the raw material lignocellulose and refine it. The next step is to verify that we have got a good dissolving pulp for textile fibre, here we work with RISE and other partners. Professor Aji Mathew has succeeded in spinning fibres from wood, and we are now scaling this up.

What do you hope to achieve?

The ultimate goal is to evaluate the new value chains, see that they are sustainable, and identify any obvious risks. We want to lay the fundaments to be able to produce valorized products from forestry residues on a large scale in a not too distant future. But we are not in the application stage, we work with basic research. My goal is that this should lead to something more than an academic study.

What is the most difficult challenge to overcome?

A challenge in assessing fundamental research methodologies concerning LCA, life cycle assessment, is that the developed methods are often not optimized in terms of solvent, heating, evaporation, purification etc. Thus, an important interface between fundamental research and an industrially relevant process is lacking. This makes it very challenging to perform LCA studies on early-stage research. The work on forestry residues will need much more development before it is ready to be evaluated with respect to LCA. Hopefully, we will gain important input data during the Mistra SafeChem programme to be able to progress to a relevant LCA.

Have you got any results so far?

We have succeeded to make dissolving pulp for fibre from bark beetle infected spruce that has the quality for regeneration. Now we will scale up and make fibre from it, which later may be used to make clothes. We are very happy with it!

-

2024-04-03 | newsFour more years – Mistra SafeChem gets go-ahead for second phase

-

2024-03-28 | newsThe 2023 Mistra SafeChem annual report focuses on more than just one year

-

2024-03-21 | newsSETAC conference on LCA will be held in Gothenburg

-

2024-02-27 | newsMistra SafeChem researchers keynote speakers at large conference on SSbD

-

2024-02-16 | newsThe Mistra SafeChem cosmetics study specially invited to EU workshop on SSbD